Exhaust Maniford Automotive Parts

True investment casting process.

Precision Machinery components made by stainless metal to satisfy clients requirement. Company aquired ISO9001 and IATF16949 certification.

Various of fabric specs accessible right here for investment castings in stainless steel, hastalloy steel, excessive chrome, carbon steel, wear-resistance, with precision Cnc machined appropriate for future assembly.

Company established in 1994, with 30 years of experience in factory area mainly focusing on quality and customer satisfaction.

Exhaust Maniford Automotive Parts for vehicle components in precision machined funding casting process, made by way of stainless metal fabric with warmth resisted, employer utilized full IATF16949 certification.

All types of cloth specs for funding castings in stainless steel, hastalloy steel,high chrome, carbon steel, wear-resistance, with precision Cnc machined appropriate for future assembly.

![]()

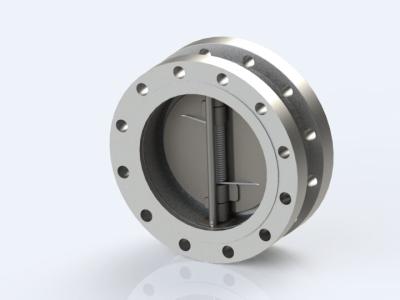

Exhaust Maniford Automotive Parts Material Spec: Stainless steel, Duplex stainless steel, Hastalloy steel, Heat resisted steel, Carbon steel, Alumium Bronze etc

Exhaust Maniford Automotive Parts Applied International Standard : ASTM,GB, JIS, AISI, DIN

Exhaust Maniford Automotive Parts Certification: ISO 9001:2015, IATF16949:2016

Exhaust Maniford Automotive Parts Predominant merchandise: Car exhaust system,intake maniford, forklift truck part, mining and development part, fabric machinery.

Exhaust Maniford Automotive Parts Testing equipments : spectrum direct reader, magnetic particle detector, cmm, microscope, hardness tester

Exhaust Maniford Automotive Parts Surface roughness: 6.3um

Length and weight: 1,000 x 620 x 380mm

Exhaust Maniford Automotive Parts weight: 0.1kg to 80kg

Exhaust Maniford Automotive Parts minimum wall thickness: 0.5mm

Shandong Yanzi Precision Machinery Co., Ltd was founded in the year of 1994 in Qihe County, Shandong Province, only 20km away from Jinan, 35km away from Jinan international airport, 350km away from Beijing, enjoying convenient ocean, land and air transportation. The foundry has a total floor area of 48,000square meters, 120 employees. With Advance equipment, high technical support, completed quality control.

We mainly produce stainless steel, heat resisted steel, wear resisted steel, carbon alloy steel, bronze and nickel base etc in investment casting process. Main products are Automotive parts, valves, pump parts, forklift truck parts, machinery parts, Hardware with 75% of our products are exporting to Japan, US, UK, Germany, Italy, Netherlands, Australia which applied to the power station, machine, chemical industry, automotive industry, medical and Hardware shop.

Company idea is become the world class supplier, with high quality, on time delivery, fast response, reasonable price to satisfy our customer needs, let’s work together to seek common development.