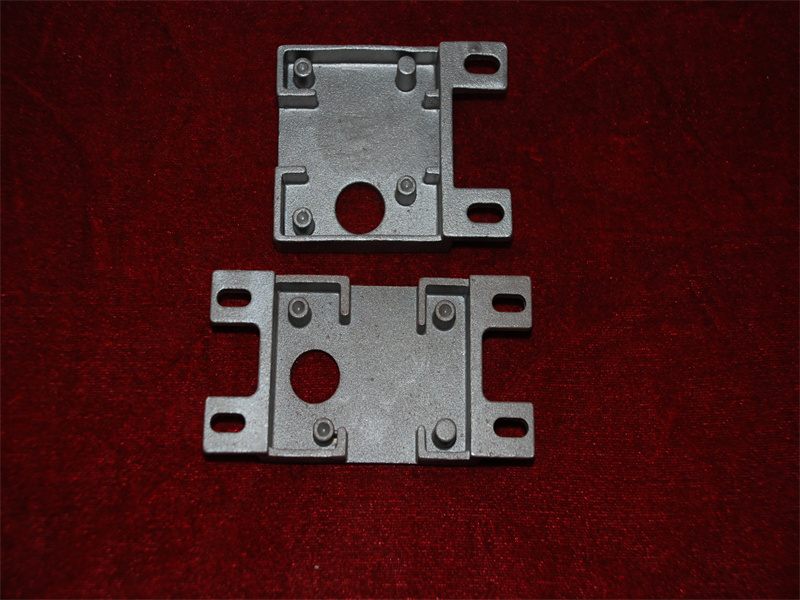

Prection Cover Casting

Protection Cover casting in True Investment Casting process.

Precision Machinery components made by means of carbon and stainless metal to satisfy clients requirement.

Company are ISO9001 and IATF16949 certified in 2009.

Various of specs accessible for investment casting in stainless steel, hastalloy steel, excessive chrome, carbon steel, wear-resistance, with precision Cnc machined appropriate for future assembly.

Company established in 1994, with 30 years of experience in factory area mainly focusing on quality and customer satisfaction

Prection Cover Casting Material Spec: We can do various materials like Stainless steel, Duplex stainless steel, Hastalloy steel, Heat resisted steel, Carbon steel, Alumium Bronze etc

Prection Cover Casting International Standard : ASTM,GB, JIS, AISI, DIN

Prection Cover Casting Certification: Aquired in 2009 ISO 9001:2015, IATF16949:2016

Prection Cover Casting Products: High speed train metal parts, machinery equipment parts,full machined metal castings, mining and construction part, textile machinery.

Prection Cover Casting Testing equipments : we have in house spectrum direct reader, magnetic particle detector, cmm, microscope, hardness tester etc to achieve customer quality needs.

Prection Cover Casting Surface roughness: 6.3um upon customers' requested.

Prection Cover Casting Length and weight: maximum castings can be1,000 x 620 x 580mm, up to 80kg weight of single casting.

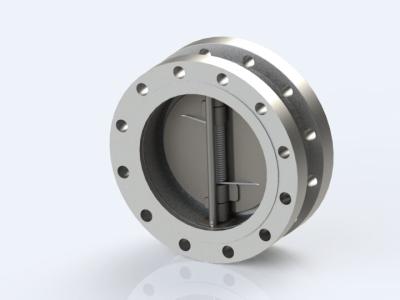

We mainly produce stainless steel, heat resisted steel, wear resisted steel, carbon alloy steel, bronze and nickel base etc in investment casting process. Main products are Automotive parts, valves, pump parts, forklift truck parts, machinery parts, Hardware with 75% of our products are exporting to Japan, US, UK, Germany, Italy, Netherlands, Australia which applied to the power station, machine, chemical industry, automotive industry, medical and Hardware shop.

Related Products

Submitted successfully

We will contact you as soon as possible